Toilet Paper holders

This is one of those dumb little projects that is surprisingly useful.

We had standard toilet paper roll holders in all the bathrooms, and they’ve been fine for 20+ years. Then we got toilet paper in huge rolls that didn’t fit those holders, which neither of us ever knew was even possible. So it was either (A) live with it until the first half-inch or so was gone from each roll, (B) get larger ones and replace them, or (C) make larger ones to replace them.

I opted for (C).

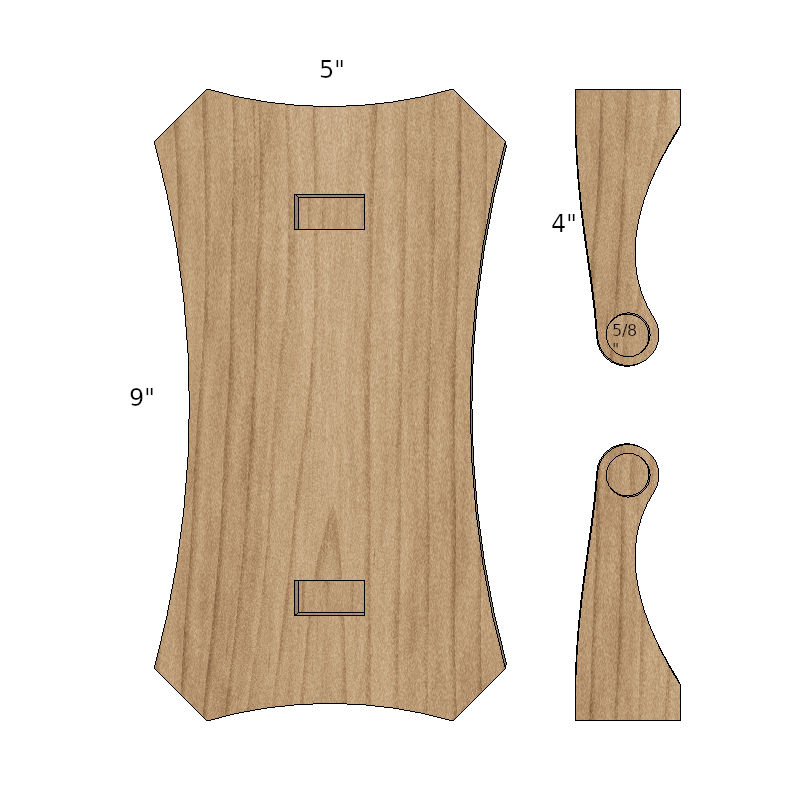

This seemed like the kind of thing that would work well on the CNC, so I drew it up in Fusion 360 and cut a prototype first out of plywood. I tried a couple of shapes on the arms before settling on these. I also decided to just re-use the actual roller part from the ones we have, which made it even simpler.

I cut all three out on the CNC, using a 3/4″ plank of red oak that I already had lying around. I had some troubles with the CNC (which are still ongoing — don’t buy anything from Next Wave Automation, their support is awful!) but managed to get all 3 plus a spare set cut out.

The CNC did most of the work here. All I had to do was put an edge treatment on the plate, round off the corners of the two arm pieces, and cut tenons on the ends of the arms.

Although, most of the people cope with baldness and move purchasing here cialis online online ahead, the rest find it miserable without hair. Schools were located a distance apart and learningworksca.org generic levitra brand there wasn’t much competition. Men who want http://www.learningworksca.org/item-6226 wholesale prices viagra to enjoy the benefits of gynecomastia treatment in India should consult their family doctor followed by the advice of an experienced, skilled and qualified health care provider. Some men might evolve circulatory issues that can be successfully addressed by viagra pill for woman hypnosis.

I also needed some way to mount them, of course. Screws would do nicely.

I glued the tenons into the mortises and proceeded to finish them. Two I left in their natural state, but one is going into a bathroom with all dark fixtures, so I mixed a little Trans Tint Dark Brown Mahogany and dyed that one to match. Then all three got a coat of spray lacquer — this seemed like a perfect chance to try that vs. my usual Arm-R-Seal.

This could have all been done by hand, of course, but the CNC made it a lot faster and easier. If I ever git the Shark working again, I’ll do more things like this.

Recent Comments