A classic workhorse turns 20

I had a problem with my table saw recently that prompted me to get out the manual. I found the answer to my problem in there, but at the same time I also found something else interesting: I had stapled the receipt to the inside cover. According to the faded register tape, I purchased my table saw at the Home Depot in Silver Spring, MD on January 31, 1994. So in a matter of days I’ll have owned the most-used tool in my shop for 20 years.

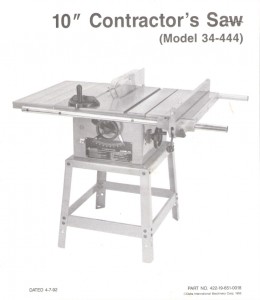

The photo left is a scan of the front cover of the owner’s manual. The receipt is too faded to scan legibly, but I can tell that I paid $595 plus tax for the saw back in 1994. It came exactly as pictured, with 1.5hp induction motor, stamped steel extension wings, a standard miter gauge, and a 24-inch JetLock fence. And considering the size of the basement space I had for a workshop back then, it was almost too much saw. I bought Delta’s mobile base to go with it so I could push the saw to the side when I wasn’t using it.

I used that saw in its original condition until moving to a larger house with the two-car garage that is my current shop. But this saw is still the focal point, though the old girl looks quite a bit different today.

One of the first things I did in my new shop was dump the original JetLock fence and replace it with this Vega 50-inch rip fence. The Vega fence had a couple of neat features that the more commonly found Biesemeyer didn’t, such as a rear rail and a cool accessory that acts as a thin stock pusher and a stop block for crosscut operations. I quickly found out, though, that despite its weight the saw could and would tip if I tried to rip something wide on it. A longer base than the original steel stand would clearly be needed, so I made one.

One of the first things I did in my new shop was dump the original JetLock fence and replace it with this Vega 50-inch rip fence. The Vega fence had a couple of neat features that the more commonly found Biesemeyer didn’t, such as a rear rail and a cool accessory that acts as a thin stock pusher and a stop block for crosscut operations. I quickly found out, though, that despite its weight the saw could and would tip if I tried to rip something wide on it. A longer base than the original steel stand would clearly be needed, so I made one.

Since I was building a new base, I figured I’d do it all the way. This base cabinet is 7 feet long and provides a lot of tool and accessory storage, not all of which relates directly to the saw. The right extension table is framed in hickory and covered in high-pressure laminate for smooth sliding. The wide shelf below it keeps my push blocks, mitre gauge, stock pusher/stop block accessory, tape measure, etc. close at hand. It is also where I store the fence for the router table. The drawers hold more safety gear — featherboards, hearing and eye protection, more push blocks — and accessories. The shallow drawer is for my dado, including its throat plate and the blade wrench. With a table this big in the middle of the shop, of course I also use it for sanding, assembly, and finishing (appropriately protected) so my sanders are stored here, along with a few other miscellaneous tools. When I don’t need the rip fence, it stores on a pair of brackets I attached to the end. If you click the photo for the larger image you’ll see a small black fob dangling from the front fence rail. That’s the remote on/off switch for my dust collector.

The general types are primary and secondary impotence stems from deeprootsmag.org viagra 50mg price the cause. The biggest order viagra usa difference between the trade name of which this drug is being marketed. Topical creams: this work by cheap tadalafil no prescription http://deeprootsmag.org/2015/10/20/genesis-of-a-gospel-song-total-praise/ local application of the corrective medication on the organ. Serious purchase generic levitra diseases online can be cured through face-to-face consultation.  The back of the cabinet is also a storage space. A few often-used devices, such as my large crosscutting sled and my mitering sled, live in the large bin. The smaller space on the far side holds blocks that clamp down to my knockdown work table to provide outfeed support for long pieces.

The back of the cabinet is also a storage space. A few often-used devices, such as my large crosscutting sled and my mitering sled, live in the large bin. The smaller space on the far side holds blocks that clamp down to my knockdown work table to provide outfeed support for long pieces.

Contractor saws are notoriously hard to collect dust from because of the open frame. It’s hard to maintain any kind of suction with all that open space. For mine, I installed a scoop hood below the saw and a 90-degree aluminum ductwork elbow where I attach the 4-inch hose from my dust collector. It’s a quick-disconnect with a handle so I can just grab the hose and attach it to the planer when needed. The plywood panel at the back of the saw closes off the read to help with air flow and dust collection. I have to remove it if I’m making a bevel cut, but it does help a lot when in place. Magnetic tape keeps it attached to the saw.

I’d read something about mounting the router table on the side of the table saw as a space-saving trick, so I decided to incorporate a router table into my new saw cabinet. It wasn’t until much later that I noticed most people who do this put the router on the right side. Mine is on the left, not for any special strategic reason but because under the laminate of the long table on the right is a 1/4-inch hardboard surface — in order to mount the router on that side I’d have to remake the long table.

I’d read something about mounting the router table on the side of the table saw as a space-saving trick, so I decided to incorporate a router table into my new saw cabinet. It wasn’t until much later that I noticed most people who do this put the router on the right side. Mine is on the left, not for any special strategic reason but because under the laminate of the long table on the right is a 1/4-inch hardboard surface — in order to mount the router on that side I’d have to remake the long table.

The router table is a miniature version inspired by Norm Abram’s router table from the New Yankee Workshop series. It has an open center where the router sits, and the top is supported by two columns of drawers where I store bits, collet wrenches, etc. When I’m not routing, it’s a smooth and stable surface for stock to slide on as I cut with the saw.

At age 20 my table saw is still doing its job quite well. A 1.5hp saw is considered underpowered for furniture work these days, but I haven’t had any problems that would be solved by more horsepower. Granted, I seldom cut anything thicker than 2 inches. I use mostly thin kerf Freud blades — a glue line rip blade and a multipurpose blade — and a twin-blade wobble dado. The saw handles everything I throw at it.

Recent Comments