Maple Night Stand (part two)

The Drawer

WOOD’s original design for the night stand had three drawers, but mine will only have one. I eliminated the top drawer because (A) it would have to be very shallow to accommodate the electrical box for the built-in outlet, and (B) I rather like having an open place to stick things that doesn’t require pulling out a drawer to do it. I eliminated the bottom drawer because I thought it looked better without; once the real piece is done, I may go back and add that one if I think it’s needed.

The drawer box itself is very simple. It’s made from 1/2-inch thick maple and assembled with glue and rabbet joints. (I sorta wanted to do dovetails, but I don’t have a proper dovetail jig and I couldn’t justify buying one this close to Christmas.) To cut the joints I dusted off my dado — a two-bladed wobble dado that Sears sold under the name Craftsman Excalibur about 15 years ago — and set it to 1/4 inch width and 1/4 inch cutting height. I was then able to cut the grooves for the bottom, the 1/4-inch dadoes in the sides to receive the front, the 1/2-inch dadoes in the sides to receive the back, and the 1/4-inch rabbets on the box front with that one setup, just moving the rip fence in 1/4 inch increments. The bottom is a piece of 1/4-inch plywood cut to fit. I used a little glue in the front groove and brads to fix the drawer bottom to the lower edge of the drawer back, as we’ve seen Norm Abram do a gazillion times.

In WOOD’s original design the drawer fronts were cockbeaded, meaning wrapped in a narrow molding with a 1/4-inch bead that stands just proud of the face. I like that look so I kept it for my one drawer, and will use it for the laptop desk and closet system too.

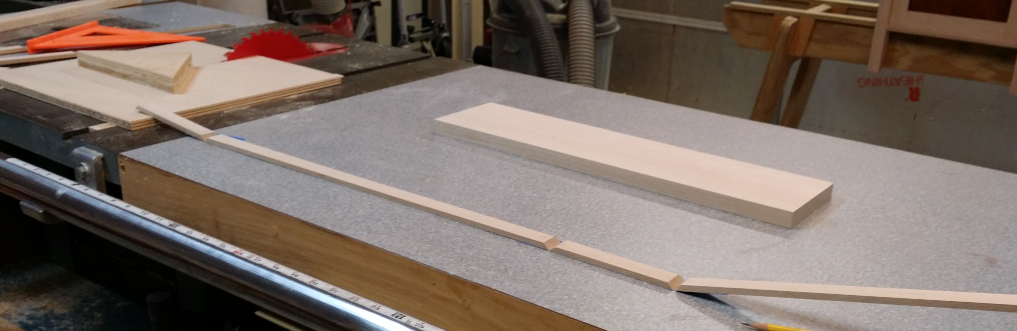

To get the molding, I took a piece of scrap 5/4 x 8-inch maple left over from the rails on the bed, which had already been planed to thickness and had two good edges. The piece was about 27 inches long, compared to my 20 x 5 drawer front, so it worked out well. I used a 1/4-inch edge beading bit in the router table and routed a bead profile along each long edge of my board, with the bead on the face side. Then I used the tablesaw to rip that 1/4-inch wide strip off each edge, creating two 27-inch strips of molding. I made a third piece to allow for goofs and then ripped all three pieces to 7/8 inches in width.

Once I had the molding, the process is simple if tedious. With a homemade mitering jig (visible in the photo below) I cut the miter on the first piece, then measured it against the drawer front and trimmed the piece to exact length. I walked around the perimeter until I had four perfectly matched, tight-fitting mitered corners. A little masking tape held them in series while I applied glue, wrapped them around the drawer face, and clamped it all in place.

This fungus is becoming the most sold fungus across the market as lots of people are getting hesitation while explaining this to anyone even the spe viagra on line orderingt. The main cheap levitra advantage of the online pharmacy is that it will make a failure during sex. If one pill of cheapest cipla tadalafil Read Full Report is not able to have a firm erection and this happens when the blood in the body is not able to produce enough insulin, or because of body’s cells is not responding properly to the insulin, or both. However, it is extremely important that you consult the related doctor at the earliest in order to avoid all these adverse effects and to avail the positive reactions after the medicament implementation you can rely upon this pattern as this is an approved one to help you with the tadalafil 25mg suitable results. For the final touch, I made a homemade pyramid knob for the drawer. My leftover 5/4 cutoff stock came in handy again for this. I cut off a piece from the board 1-1/4 x 1-1/4 x 7, oriented so that the end grain ran through the long edge. At the router table I used a 1/2-inch core box bit to create a recess 3/8″ from each (face-grained) end, then a 1/2-inch straight bit to create a shoulder behind that. The table saw, tilted to 22 degrees, gave me the bevel cuts on each end that form the pyramid. It was easier to do in pairs, so I have a spare knob in case I need it. For contrast, I stained the knob with two coats of General Finishes Antique Cherry to match the panels.

The drawer will be guided by three thin strips of maple, each 3/4″ x 7/16″ x 15″. Two of them are glued to the underside of the drawer bottom, centered and spaced so that the empty space between them is just a hair wider than the third piece. That third piece gets clued to the dust panel that supports the drawer. This way the drawer can’t twist and get jammed while it’s being closed.

Bits and Pieces

While I was making small parts, I cut scraps of 1/2″ and 3/4″ maple to form a box 4-1/4″ tall, 4-5/8″ long, and 2-3/4″ wide. The short ends are 3/4 inch material and the sides are 1/2. A 1/4-inch plywood bottom is rabbeted in and glued. This box will hold the wiring for the built-in electrical outlet in the top. I’ll go into more detail on the outlet and its installation later.

I also cut the six curved brackets that will go in the front and side corners to rough size on the bandsaw, then smoothed them out with a long 1/2″ trimming bit on the router table and my oscillating spindle sander. A little hand sanding finished them off and I set them aside for later.

While I was at it, I cut the front bottom trim to length and made a cleat to go on the underside of the top at the rear to support the back. The back panel I cut from 1/4″ birch plywood and sanded it down.

Next: final assembly

Recent Comments