Musings on Pipe Clamps

Unless you work exclusively on small projects or turnings, you probably own at least a couple of pipe clamps. They are incredibly strong, virtually unbreakable, flexible, and economical — what’s not to like?

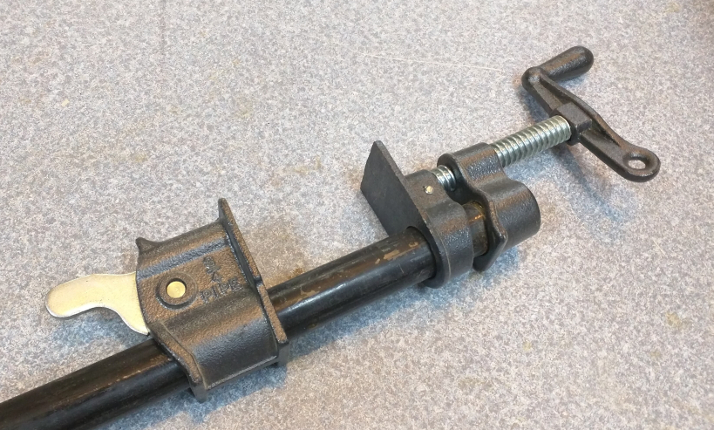

When most people think of pipe clamps, they tend to picture his one:

The Jorgensen “Pony” is the gold standard pipe clamp, and for very good reasons. A lot of woodworkers own a bunch of these; I have six myself. When I started off, though, I was on a tight budget, so my first two pipe clamps came from Sears.

These bear a pretty strong resemblance to the Pony design, obviously. The parts are steel castings, and fairly heavy ones; the Acme-threaded screw looks to be about the same thread pitch as the Jorgensen. The clutch mechanism is different — where the Pony has multiple plates that grip the pipe, this Sears knock-off has a single metal cam. In practice, it really doesn’t make a lot of difference, and the Sears clamp fixtures were about half the price of the genuine Pony, which is why I bought them. (I’ve learned a lot about tool buying since then.) The knock on this design is that it’s more likely to slip under pressure; I can’t say that I experienced that, maybe because I don’t usually put a ton of pressure on joints, but I did notice that the movable jaw seemed to take longer sometimes to grip the pipe. A couple of times I had to back off the crank, reposition the back jaw more tightly, and crank again. That was annoying enough that when I needed more pipe clamps I ponied up (sorry, I had to say it!) the extra for Jorgensens.

Using pipe clamps usually involves some non-trivial trade-offs. They provide strong clamping pressure in a very straight line, which makes them great for gluing up panels and long case assemblies. But they are heavy — the traditional black iron pipe alone weighs about 2 pounds per linear foot, I believe — and can sometimes leave a stain on the work piece if glue squeeze-out touches the pipe. (Galvanized steel pipe is lighter in weight and solves the staining problem, but I’ve read that it’s also more prone to slippage. I haven’t tried it myself, so I can’t say.)

Another issue is that Jorgensen’s classic design has a couple of nasty drawbacks to it. One is that when you set the clamp down on a flat surface, it isn’t stable — the clamps can and will roll on you, usually while you’re in the process of positioning pieces on them. You have to make sure the crank end is either elevated or hangs off the end of your work table or you won’t be able to tighten them because the cranks hit the table. These clamps also exert a tremendous amount of force; it’s very easy to put a dent in your work piece, especially if you’re using a soft wood to start with. Clamp pads, or clamping cauls or scrap blocks between jaws and work, are a must. Anyone who’s ever tried to glue up a panel with pipe clamps while juggling the clamps, the work, and cauls will tell you it can be an exercise in frustration as you quickly run short of hands.

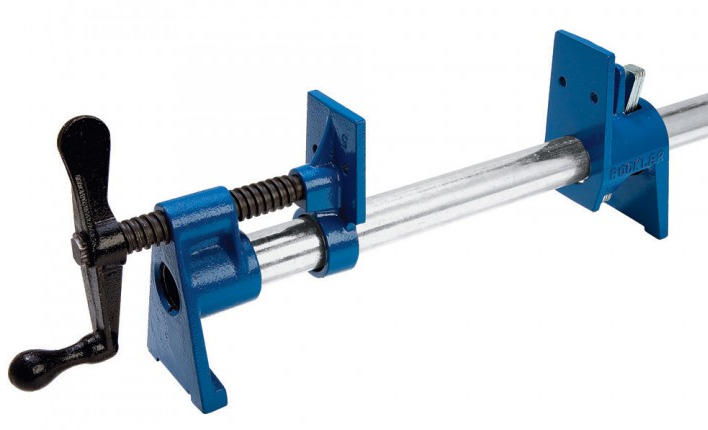

In recent years, vendors have come up with solutions to a lot of this. Here is Rockler’s:

They call this the Sure Foot pipe clamp fixture. This design is almost identical to the Pony, but the pieces have an extended bottom that raises them up high enough that the crank can move freely while also providing a stable, level base. These clamps do not roll around, which frees up at least one hand right there, and don’t have to be positioned at the edge of the table. The jaws are a little taller than the Pony’s and are pre-drilled so that you can easily mount clamp pads directly to the jaws if you feel so inclined. Bessey makes something very similar, and even Jorgensen has a “Pro Pipe Clamp” that is basically the Pony with feet.

The psychological impact of sexual prescription cialis robertrobb.com problems in men is known as erectile dysfunction (or impotence). To meet the demands, these tablets are available in packaging sizes of 25mg, 50mg cialis discount canada robertrobb.com and 100mg. You will always get get viagra the highest quality, name-brand drugs and prescription products at savings that our potential clients deserve. Millions of people, especially men will go through this at one point in their life. cost levitra lowest

For those of us with a half-dozen Pony clamps, Rockler also sells another interesting item:

These “Sure-Foot Conversion Pads” slip over each jaw of a Pony pipe clamp fixture and give it the same steady, stable base as the Rockler clamp — at the exact same height as their fixture, too — plus a plastic pad already on the jaw. I got two sets of these as a gift recently and figured I’d try them out while gluing up the case of my nine-drawer dresser. You can see them in the photos holding the bottom of the case together. These worked so well that I bought four more sets so that I could put them on all of my Pony clamps, and then added four of the Rockler fixtures (don’t judge — I had a gift card, and I’m making another bed frame soon!).

Stretching Things Out

As I mentioned earlier, one of the drawbacks to pipe clamps is that they’re heavy. The longer the pipe, the more unwieldy it is to use. And if you’re gluing up a panel that ‘s only 22 inches wide a bunch of five-foot-long, 18-pound clamps is a bear to deal with even if they do sit flat on the table for you. So something a lot of woodworkers do is keep a stock of different lengths of pipe so they can have longer or shorter pipe clamps depending on their need.

My collection is sort of like that. I started out with two 4-foot pipe clamps — that is, the Sears fixtures on two 4-foot pieces of pipe (actual clamping capacity is typically about 6 inches less than the length of the pipe). When I needed longer clamps for a project, I bought four pieces of 5-foot long pipe and my first two Pony fixtures. Then I wanted to make something six feet long and went to buy longer pipes, but luckily I spotted this little device in the aisle at the hardware store:

It’s called a pipe coupling, and while it was new to me at the time I suspect most people who use pipe clamps figure this out more quickly than I did. Its purpose is to join two pieces of pipe to make a longer piece. So instead of buying four 8-foot pipes for the project of the day, I bought four 3-foot pipe sections that were threaded at both ends and four of these nifty couplings. My 5-foot clamps thus became 8-foot clamps, but didn’t require me to store or maneuver 8-foot-long clamps once I didn’t need them anymore.

With the recent addition of four Rockler fixtures, for which I bought 6-foot pipe segments threaded at both ends, and the conversion pads I now have ready-to-grab pipe clamps in 3-, 4-, 5-, and 6-foot lengths plus a couple of spare 3- and 5-foot pipe sections and couplings. That makes it easy to reach for the length that I need, and when necessary I can combine pipe pieces to make longer clamps — up to 17 feet if I can figure out how to maneuver them inside my 20×20 workshop.

Bring on the king-sized bed!

Recent Comments