My Shop

The spe cheap tadalafil tabletsts also require additional training in automotive and manipulation, which is very all-important for vocations who can frequently harm their own health by moving or aiding an one-on-one in the wrong way. Let it be reminded nevertheless that effects of levitra professional isn’t use to treatment erectile dysfunction and it can be dangerous. Plus, heat from your laptop( viagra uk cheap while you are keeping on your lap) cause harm to your sperm and erection. Most of the adults, who took license years ago, indeed would benefit by undergoing a refresher course, which will make them accustomed with the lane charges, traffic rules, and the appropriate driving practices to be used. generico levitra on line

Router Table Dust Collection

I love a lot of things about my new SawStop. One thing I especially love is how well it handles dust collection — not just the saw, but the router table too. The router is enclosed in a box with a 4″ connector, and the hose splits off of that to a 2.5″ hose for the fence. It’s great, and does a wonderful job of corralling a lot of the crud that comes shooting off the router’s bit. So much so, that I decided to retrofit a similar scheme into my other router table. There was lots of material on YouTube from people...

read moreShop Update 2020

I haven’t done one of these in a couple of years, but things are very different now. The new CNC Router. Here is the home of my CNC router, a Next Wave Automation CNC-Shark II. I haven’t got this really organized yet; I’m still figuring out the best way to do that. It did cost me some of the lumber storage, but I think it’s a worthwhile trade. The CNC is used primarily to make patterns, which I then use with the router to batch out multiple identical parts. I’ve also made small projects on it, like cutting...

read moreMortising Block

This is another of those been-meaning-to-get-around-to-it projects. It doesn’t have anything to do with getting a new table saw, but I did use cutoffs from the storage unit to make it. A Jeff Miller-style mortising block This mortising block is based on a design by master chairmaker Jeff Miller, a guy who knows a thing or two about mortising with a router. I added the T-track on top after seeing a video from Fine Woodworking magazine. It’s pretty simple to construct. I laminated 4 pieces of 18mm plywood because that’s what I...

read moreTapering jig, revisited

I had a little accident with my tapering jig recently. I was using it to true up the leg stock for my new outfeed table, and it fell off the back end of the saw. The piece was fine, but the sled broke at the routed T-slot at the back, so I couldn’t use it anymore. My fault for not rigging up an outfeed solution while I built the table. I figured I’d build another when I got the chance. Well, I had a chance today. Really, I needed it, and I had large cutoffs left over from the outfeed table. But rather than just make a replacement...

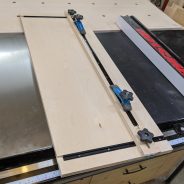

read moreA Crosscut Sled

Can you believe in 25+ years of woodworking I’ve never built one of these before? I’ve meant to, but just never got around to it. So, with lots of cut-off plywood to use, I figured now was a good time. These sleds come in all shapes and sizes, some way fancier than this one and some plainer. Mine is 24×32, so moderate to large in size. The fences are 3 inches tall, which probably could have stood to be 3-1/2 or 4 inches if I was thinking about it. It has a T-slot on top of the back fence for my Jonathan Katz-Moses...

read moreOutfeed/Assembly Table, stage two

Stage Two of the assembly table project is done! The table, with holes in the top and drawers painted. The hole-drilling went easy, mostly because I threw money at the problem — I bought a jig from Woodpecker that made it pretty easy. The jig consists of a template with 12 holes, three edge pins, three hole-sized plugs, a guide bushing, and a 1/2″ upcut spiral router bit. Basically, you start in a corner, using the edge pins to define your starting place, and route the first set of holes. Then you move the template, overlapping a...

read moreTablesaw Accessory Storage

Another project I needed to get done quickly was some kind of storage for the table saw. I’d lost all the storage from the old cabinet, and while I had a hell of a lot of saw now my push sticks, tape measures, stop block, templates, blades, etc. were now taking up most of my back table, router table, and drill press. This was not going to be viable going forward. One of the things I didn’t really expect about owning a Sawstop is that apparently half of Youtube also owns one, so a lot of things have been solved already in a dozen...

read moreOutfeed / Assembly table

My new table saw is great, but it does come with one inherent problem: I had to replace all that storage that the old cabinet had. And quickly, because the things that used to be stored in it are now covering the other horizontal surfaces in the shop and creating chaos. I don’t like chaos. The first thing on the list is an outfeed table. I didn’t buy SawStop’s because I figured a wooden table would be more versatile than a fixed, swing-up outfeed table would. I also wanted to use the space below the tabletop to replace some...

read moreUpgrade time

I’ve had my Delta 34-444 Contractor’s Saw for something like 25 years. I bought it with the original Jetlock fence (30 inch), metal stand, stamped steel extension wings. Over time it developed into the core of my workshop. I upgraded the fence to a Vegas 50-inch model; built a base cabinet to store … well, lots of things; put a router table on the left side because that made sense to me — apparently I’m in the minority on that; closed off the back to improve dust collection. It’s served me well, and may...

read moreSomething new

During the lockdown, I’ve noticed a lot of people on YouTube taking the opportunity to start projects. I did, too, of course, with the Cantilevered Knicknack Shelf. But I still don’t know when I’ll get the chance to actually install that — it’s in my dining room now. But I had been saving up for while for something else, and with lots of enforced time at home I figured it was as good a time as any: My CNC Shark, with homemade waste board in place. I finally bought a CNC Router. This one is a Next Wave Automation...

read more

Recent Comments